How to Read a Water Pump Curve

- By Scott Carter

- Jan 31, 2017

What do all those lines mean? It looks so confusing! How do you even understand what it means? Looks like a poorly made paint by numbers picture to me! These are just a few things I have heard from people when they initially look at a pump curve.

Looking at a pump curve can be an overwhelming task, unless you know what you are looking for. But the truth is, you don’t need to have an engineering degree to understand a pump curve.

Yes, pump curves can be confusing, especially as some pump curves are more technical than others. Hopefully by the time you finish reading this post you will be able to look at even the more technical curves and find the most basic information necessary to finding the right pump.

Think of this post as a layman’s guide to pump curves. We will look at a few basic pump curves. In future posts we will look at more technical pump curves and how to interpret the corresponding data for more advanced applications.

For the sake of clarity in this post however, we will look at one of the more commonly used pumps, an electric end-suction centrifugal water pump. We will also look at interpreting the most basic information (head/flow) needed to help you pick out the right water pump for your given application.

The truth is, when in doubt, ask a Water Pump Specialist for help in finding the correct water pump for you. We would be more than happy to help you pick out the right pump!

What is a Pump Curve?

A pump performance curve is simply a graph or chart that represents the performance capabilities of a given water pump. A pump manufacturer conducts a variety of tests and the findings are then reflected on a graph, which we refer to as the pump curve. A pump curve will typically show not just the maximum capabilities of the pump, but just as important, many pump curves will give information helpful in determining the best efficiency point (BEP) for flow rates as well as reflecting the preferred operating range (POR) of the water pump. Once you know how to read a pump curve you will be able to determine what to expect from your water pump: how many feet is it capable of pumping, how many gallons per minute, and what will be the ideal operating performance for efficiency, as well as other important information.

The Most Common Information a Pump Curve Provides

- Total Dynamic Head

Total dynamic pump head, most commonly referred to as total head, concisely stated is the height that a water pump is capable of raising a liquid. It is the total vertical distance that the pump is capable of ‘pumping’. It answers the question, “How high can it pump?” The greater the pressure, the higher the head. The lower the pressure, the lower the head.

- Flow Rate

Flow rate, or rate of flow, is the total maximum amount of liquid flow that a pump can produce during a specified period of time. It is almost always measured per minute and most pump curves will show either gallons per minute (GPM) or liters per minute (LPM), or commonly both. Flow rate answers the question, “How many gallons can I expect?” The greater the pressure, the higher the flow rate. The lower the pressure, the lower the flow rate.

- NPSHr (Net Positive Suction Head Required)

Net positive suction head required is the minimum amount of pressure or force of energy that is required at the suction port (inlet) to overcome the losses from friction that are caused between the suction head/nozzle (inlet) and the eye of the impeller, without causing vaporization (cavitation) of the liquid being pumped.

- Best Efficiency Point

Every pump has a best efficiency point (BEP) and many pump curves will clearly show the BEP. BEP is the rate of flow and the total head at which a pump efficiency is at a maximum at a given motor speed and impeller diameter.

BEP is a combination of the head/flow rate as it corresponds to the highest efficiency. BEP directly corresponds to the input horsepower of the motor required to drive the pump and the horsepower created by the flow of water created by the pump.

For a pump to be 100% efficient the input horsepower needed would be equal to the water horsepower being created. No pump is capable of 100% efficiency and as a result every pump will require more horsepower input from the motor than it is capable of generating in water horsepower.

Think of the BEP as what a baseball player would refer to as the “sweet spot” of the bat! Studies have shown that by operating within the BEP, the pump/motor life is extended. This not only minimizes the cost of repairs, maintenance, and replacement, but also the costs incurred during a down time of production for a pump that is no longer operational.

- Preferred Operating Range (POR)

Referred to as the preferred operating range or preferred operating region. A pump will run best the closer it is to the BEP. For this reason, The Hydraulic Institute has determined that the preferred operation range as it pertains to water flow is between 70%-120%. Most manufactures will recommend a POR that is between 80% and 110% as operation in the POR has direct implications on the life of the pump as well as power consumption.

Pump manufactures give a variety of information on their pump curves. Some are more detailed than others. However, most manufacturers will offer more detailed specs, requirements, additional curves, etc. in their product manuals. But the most basic information that the average consumer needs typically boils down to 2 items: Total Pump Head & Gallons Per Minute

Reading a Pump Curve

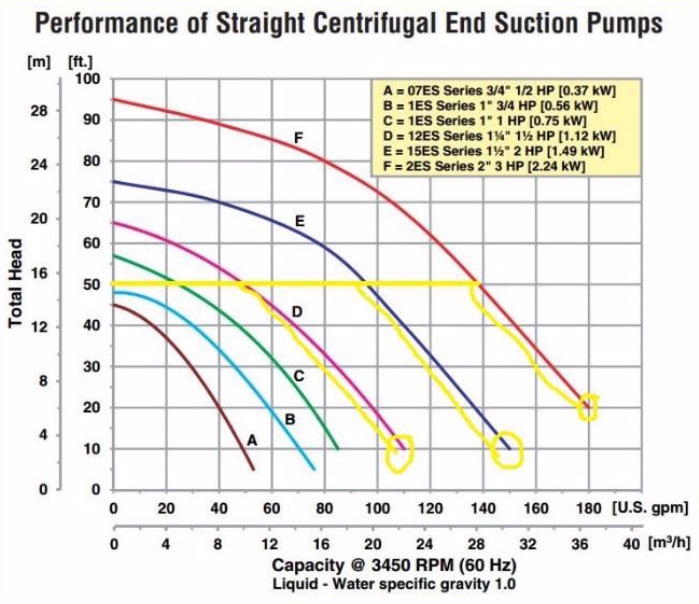

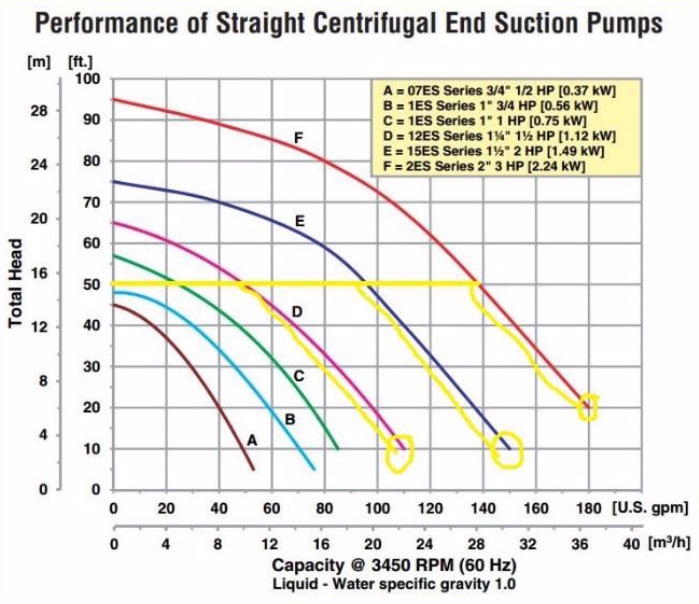

Let’s look at an example situation to help you pick out the right pump for your application using just pump head and gallons per minute to help us come to a decision on the right pump.

Situation #1: You are replacing an old pump that already has the pipes in place that are 2” going into the pump and 2” going out. The old pump is pumping water from a 5,000 gallon tank and pumping the water to a second tank that is 50 feet above the first tank. Your old pump was pumping approximately 100gpm (gallons per minute) and you would like to try to get a pump that will perhaps get you to 150gpm due to increased production demands.

So we can determine the following:

- You need a pump with a 2” inlet diameter and a 2” outlet diameter

- You have a minimum pump head of 50 feet

- You would like a pump that will give at least 150gpm

Looking at the pump curve below, which of the following 2” pumps will work for your application?

Step #1: Start with your required pump head (50 feet) on the left-hand side of the curve

- We can see that pumps A & B are below our required head, so we can rule them out.

- We now have 3 pumps on this curve that meet our total pump head requirement of 50ft.

Step #2: Determine which pump is capable of 125gpm or more

- From the left of the curve, starting at 50ft, draw an imaginary line to the right.

- Then follow each pump curve down towards the GPM.

- We can see that pump D will give us the 50 feet of head we require but will only give us 110gpm. It’s probably similar to the pump you are replacing.

- Pump E will meet our 50ft head requirement (it’s capable up to 75ft) and at 50ft head it will give us 145gpm. Pump F at 50ft of head will give us 180gpm.

Step #3: Decision Time!

You have 3 pumps to choose from that meet your requirements but you still have a few things to consider:

- Pump D:

- Pro: similar to the pump you are replacing

- Con: no real increase in performance in GPM (110gpm total)

- Pro: guaranteed to be lower cost than pumps E & F

- Pump E:

- Pro: increase of 45gpm compared to your old pump (145gpm total)

- Pro: gets you close to your desire of 150gpm

- Con: 5gpm lower than your 150gpm goal

- Con: higher price than pump D

- Pump F:

- Pro: increase of 80gpm compared to your old pump

- Pro: 35gpm greater than pump E

- Pro: gets beyond your desire of 150gpm (180gpm total)

- Con: higher price than pumps D & E

Conclusion

As you can see there are many considerations to look at when picking out a pump. And we only looked at one example and a simple one at that!

While there is a lot of information available to you, the consumer, finding the most basic information is not as hard as one would think. Just remember, the best thing to do is to ask an expert if you are not sure! But now that you know the most basic details as you look at a pump curve, you will be better prepared to make the best decision on the right pump.

At Absolute Water Pumps we would be more than happy to answer any questions you have as you look for the perfect pump! Feel free to give us a call at 1-888-264-2189 for any of your water pump needs.

At Absolute Water Pumps, we know transparency is important. We’re proud to provide our customers with as many made-in-America water pumps as we can. Perhaps now more than ever, consumers are concerned with where and how their products are being made. Do companies have manufacturing facilities in China? The Philippines? The United States of America? Do they make responsible and ethical business decisions? We’re happy to partner with a number of made-in-America water pump manufacturers, and we believe our clients should know exactly where and who is making your water pump systems.

At Absolute Water Pumps, we know transparency is important. We’re proud to provide our customers with as many made-in-America water pumps as we can. Perhaps now more than ever, consumers are concerned with where and how their products are being made. Do companies have manufacturing facilities in China? The Philippines? The United States of America? Do they make responsible and ethical business decisions? We’re happy to partner with a number of made-in-America water pump manufacturers, and we believe our clients should know exactly where and who is making your water pump systems.